In 1909: rotating portable mountain:

Source: http://aviadejavu.ru/Site/Crafts/Craft22261.htm

Rick Masters wrote:http://www.newspapers.com/clip/1641318/ ... extension/

This is very interesting because the motor could be used to gain significant altitude through ascending spirals, then the cord could be released for freeflight. This would be much safer than towing. The lightweight power cord could play out from a ground-based reel. The craft could be bungee-launched from level ground (like Blacks Beach) or run off a very low hill. The small sustainer motor would allow an easy climb. It could also be used with onboard batteries to avoid draining them during the power-hungry climb, thus saving them for intra-thermal or canyon jumping in ridge lift. Power could be supplied from a ground-based generator or utility power plug-in. Have you toyed with this concept yet? Do you know about lightweight conductors like carbon fiber?

We don't even need such lightweight conductors to soar Torrey today using this concept - but it's neat to think about. You could climb a mile or two with a lightweight cord. Put a little parachute on it for drag when you reel it back in from the ground. If the kid did this 115 years ago, we must all be fu**ing stupid not to have done this yet. It could even replace towing altogether!

You would need

1) a foldable prop

2) a shaft

3) cheap lightweight AC electric motor (no magnets)

4) mounting hardware

5) a female plug

Maybe 10 pounds. Maybe less.

Carbon nanotube wires and cables: near-term applications and future perspectives.

Jarosz P1, Schauerman C, Alvarenga J, Moses B, Mastrangelo T, Raffaelle R, Ridgley R, Landi B.

Abstract

Wires and cables are essential to modern society, and opportunities exist to develop new materials with reduced resistance, mass, and/or susceptibility to fatigue. This article describes how carbon nanotubes (CNTs) offer opportunities for integration into wires and cables for both power and data transmission due to their unique physical and electronic properties. Macroscopic CNT wires and ribbons are presently shown as viable replacements for metallic conductors in lab-scale demonstrations of coaxial, USB, and Ethernet cables. In certain applications, such as the outer conductor of a coaxial cable, CNT materials may be positioned to displace metals to achieve substantial benefits (e.g. reduction in cable mass per unit length (mass/length) up to 50% in some cases). Bulk CNT materials possess several unique properties which may offer advantages over metallic conductors, such as flexure tolerance and environmental stability. Specifically, CNT wires were observed to withstand greater than 200,000 bending cycles without increasing resistivity. Additionally, CNT wires exhibit no increase in resistivity after 80 days in a corrosive environment (1 M HCl), and little change in resistivity with temperature (<1% from 170-330 K). This performance is superior to conventional metal wires and truly novel for a wiring material. However, for CNTs to serve as a full replacement for metals, the electrical conductivity of CNT materials must be improved. Recently, the conductivity of a CNT wire prepared through simultaneous densification and doping has exceeded 1.3 × 10(6) S/m. This level of conductivity brings CNTs closer to copper (5.8 × 10(7) S/m) and competitive with some metals (e.g. gold) on a mass-normalized basis. Developments in manipulation of CNT materials (e.g. type enrichment, doping, alignment, and densification) have shown progress towards this goal. In parallel with efforts to improve bulk conductivity, integration of CNT materials into cabling architectures will require development in electrical contacting. Several methods for contacting bulk CNT materials to metals are demonstrated, including mechanical crimping and ultrasonic bonding, along with a method for reducing contact resistance by tailoring the CNT-metal interface via electroless plating. Collectively, these results summarize recent progress in CNT wiring technologies and illustrate that nanoscale conductors may become a disruptive technology in cabling designs.

http://www.ncbi.nlm.nih.gov/pubmed/21984338

Clipped by Rick Masters from The Salt Lake Tribune, 4 Dec 1910, Sun, First Edition

Uses energy from ground power source to helicopter up using electric cords; then kites to generate electricity; then for precision landing the ground-source power could be used again; they have considered for some emergencies that line could be dropped and the wing could be glided home by remote controls of aerodynamic surfaces. Makani Power image wrote:

See the many photos and story over the FEGS at http://www.skywindpower.com/science_generators.htm

Wessel plunged over the side of the ramp without cheating gravity even for a moment. His machine was smashed, with one wing destroyed.

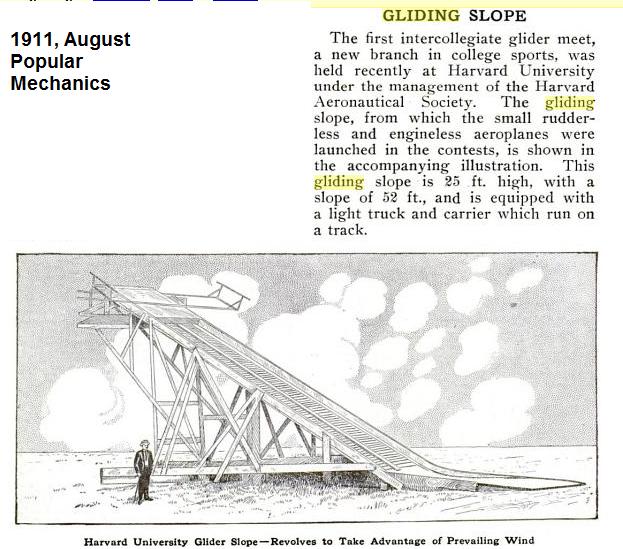

Legend Of The Fall. The Great Wessellini’s launch ramp was a wooden affair six feet high and 32 feet long situated below the Campanile and aimed at Memorial Stadium.

JoeF wrote:BobK, that skim-board kiting gliding history note is very on topic. Thanks.

===============================================================

Optional power sources regarding the scene posted two posts up:

1. Have the Torrey Hawks haul-line team be up in the public parking lot or street; they could get better traction on their shoes.

2. Anchor a kite much out at sea; have the kite system lift water bags. Then upon "Go!" trigger the drop of the water bags vertically, but have the HG tow-up line go up to the pulley and to the dropping water bags. A kite-system safety downing line is key for safety and for closing the system for the day. A slack return line RL is used during towing up of HG; the RL lets team bring the tow line back for another Torrey Hawk or US Hawk to be towed up. Notice that the line haul team does not have to run on the beach; in this portable mountain version, the team needs only struggle to lift the water to altitude, hold the line until Go! is given. [[Alternative workarounds can be effective, see below.]]

Want to have team not work so hard to lift the water bag for recharge? Then design and install a kite control system that changes AoA of the train wing element that lowers P2 to near water level; then pull slack line of tow line to just taut; then change AoA of wing set again for heavy lift-back; the kite train then will lift the water using wind energy. Beach team would then use capstan to simply let out line as the P2 goes up with water bag near P2 to altitude ready for another launch; hence much less beach footprint and much less muscle involvement; smaller team too.

Want a near alternative that does not even use water bag? Consider using only a kite-system anchored sufficiently out to sea. Have AoA control of kite system. Lower the kite system wing set; have line from the main tether going to HG at shore or near-shore. Have a first anchor for the main system; then have a second anchor with pulley through which the HG tow line paths to an upper point on the kite system. When the AoA of the kite system is set for lift, then the HG tow line is pulled through the second anchor's pulley; and then the HG is towed to altitude. Plan carefully the positions of the parts. Respect air traffic and mark the lines that will be in air and on water surface. Have also a RL that is slack during HG tow up; use the RL to bring back the line end for towing another Torrey Hawk. Drawing may come later on this alternative.

Smarts for any of these systems will be important. Knowing the wind and distances and lengths and involved speeds and forces will play their spirits.

~ JoeF

Torrey Hawk

US Hawk

Mo Hawk

Users browsing this forum: No registered users and 113 guests