Excellent practical approach for a family of solutions, BobK!

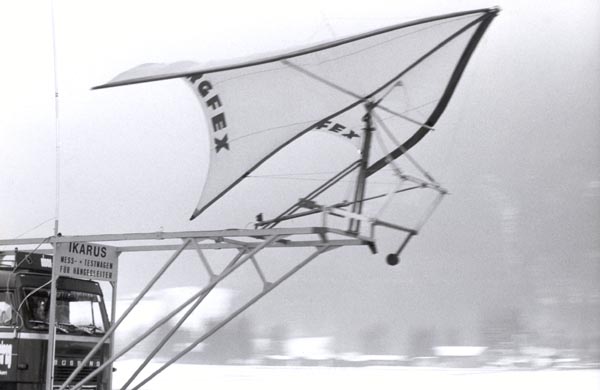

Mod-05-Falcon-1-195 might be a first in that family. Hacksaw is ready (or cut-off saw!). Velcro committee is waiting; or the Zipper Crew. Coupling captain is alert to core and oversleeve. Logistics secretary is ready with notebook. Tangle clerk is an avoid-knot expert. We cannot miss! The assembly will be good for warming up body systems. The system check will build intimacy with wing; call her

Sally Soar or

Sore Sally, or

Sore Sam or

Sam Soar, your choice. ... on the bus I go, on the bus I go, happy as a cricket.

I'll do a mod to 5' on the long battens too! Hey, Greg D., here is Sally, my

Mod-05-Falcon-1-195; no charge for you to test fly it!

Sail-connect explorations: == Duct tape

== Velcro parts

== Magnets

== Corded clasping

== Sticky wrap

== Snap-in-channel (Zip-Lock)

== Rim cord in groove

== ? (open to committee work)

==============================

Tube-coupling explorations for available cut macro tubes

== Plug core and oversleeve

== Terminals: threaded join

== Splints and whipping

== Locking clamps

== Mating flanged inserts for bolting

==

== ? (open to committee work)

====================

====================

Yet, progress on other families of solutions will occur.

Home

Home